The RLD Performance 6.1 Hemi CNC cylinder head has more velocity, average flow and peak flow than the GM Corvette LS7 CNC cylinder head. The Late Model Hemi program includes the most highly developed Hemi cylinder heads on the market with stage 1, 2 and 3 intake manifolds, a custom camshaft line, custom pushrods, a new shaft rocker arm system, custom racing spring kits and custom titanium valves. We build parts that fit and stand up to the abuse of racing.

Maximum factory valve lift is .550. To use a camshaft with higher lift the valve guides must be cut down are resized for new seals, locators, springs and retainers. RLD Performance sells the guide cutter and spring kits to maximize the Hemi cylinder head performance.

Cylinder head development included a complete work up of both the 5.7 and 6.1 i.e., analyzed, installed, modified and flow tested. The combustion chambers were CNC quench pad qualified, both valves and seats were analyzed for shape and size. Intake valve and seat ranges were tested from 2.055"-2.200". Exhaust valve and seat ranges were tested from 1.5" -1.7". Six valve seat angles as well as four valve head angles were included. Valve length is critical and GM valves are not advisable. For performance applications a single groove bead lock is far superior to a factory triple groove rotating lock. Valve train improvements were identified including fitment. Concepts like piston to valve clearance, valve length and valve guide stability for maximum performance were explored.

Several competing aftermarket heads were baselined for comparison. Several intake port shapes were developed for CNC replication. Certain combinations emerged as superior, the most practical and the most economical to utilize. In the end, a new machining process, Trade Named from US Patent Office as "Flowline Machined", emerged as the best flowing model port as shown below. Due to OEM core shift, flow may vary.

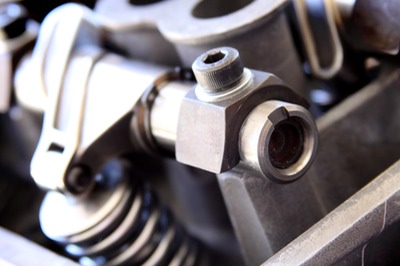

A custom shaft rocker arm system was developed in conjunction with PRW to stabilize the valve train. A complete custom camshaft line was developed for maximum performance. Conical and dual racing springs were developed up to .875 lift. More about camshafts and valve train can be found (here...). Learn about maximum horsepower for this platform (here...). Dyno sheets can be found (here...) By looking at the flow data below it is too bad that you cannot use a 5.7 head on a 6.1 for added compression or a 6.1 intake manifold on a 5.7!

CombC=73 70

RunnerCC=188cc 58cc 270cc 85cc

Valve= 2.080/1.60 2.200/1.61

RLD CNC 6.1 VS 6.1 Stock Head VS RLD CNC 5.7 Head

Lift I E E/I I E E/I I E E/I

.100 84 52 62% 71 62 89% 73 60 82%

.200 171 100 58% 158 132 84% 154 122 79%

.300 250 133 53% 228 175 77% 225 167 74%

.400 310 179 58% 278 200 72% 275 196 71%

.500 355 215 61% 299 213 71% 305 216 71%

.550 369 237 64% 303 216 71% 316 222 70%

.600 377 246 66% 307 217 71% 316 226 72%

.650 381 255 67% 307 216 70% 319 226 71%

.700 382 257 73% 307 220 72% 312 225 72%

.750 383 262 68% 309 220 71%

AVG 306 194 63% 257 187 73% 255 185 72%

RLD CNC 6.1 VS GM LS7

Lift I E E/I I E E/I

.100 84 52 62% 71 50 70%

.200 171 100 58% 145 120 83%

.300 250 133 53% 222 158 71%

.400 310 179 58% 271 192 71%

.500 355 215 61% 315 207 66%

.550 369 237 64% 332 214 64%

.600 377 246 66% 348 219 63%

.650 381 255 67% 350 220 63%

.700 382 257 73% 352 221 63%

.750 383 262 68% NA NA

AVG 306 194 63% 276 178 64%